Home / All / Sinter-plate Dust Collector / ACMAN Sinter plate Dust Catcher Sintered PE Polyethylene Filter Delta Sintered Porous Element Dust Collector

Categories

- Sinter-Plate Filter/Sinterlamellenfilter

- Cartridge Dust Collector

- Wet Dust Collector

- Cyclone Dust Separator

- Sinter-plate Dust Collector

- BIBO Filter Housing Unit

- Welding Fume Extractor

- Pharmaceutical Dust Collector

- HVAC Dust Collector

- Silo Bin Vent Dust Collector

- Powder Coating Dust Collector

- Laser Fume Extractor

- Centrifugal Fan

- Other Dust Collection Machine

- Baghouse/Bag Type Dust Collector

- Other HVAC Ventilation Equipments

- Pleated Dust Filters/Air Filters

- Explosion Proof Devices

- Vehicle Exhaust Hose Reels

- Keller Lufttechnik Type Dry Separator Dust Collector

ACMAN Sinter plate Dust Catcher Sintered PE Polyethylene Filter Delta Sintered Porous Element Dust Collector

Detail Information

ACMAN Sinter plate Dust Catcher Sintered PE Polyethylene Filter Delta Sintered Porous Element Dust Collector

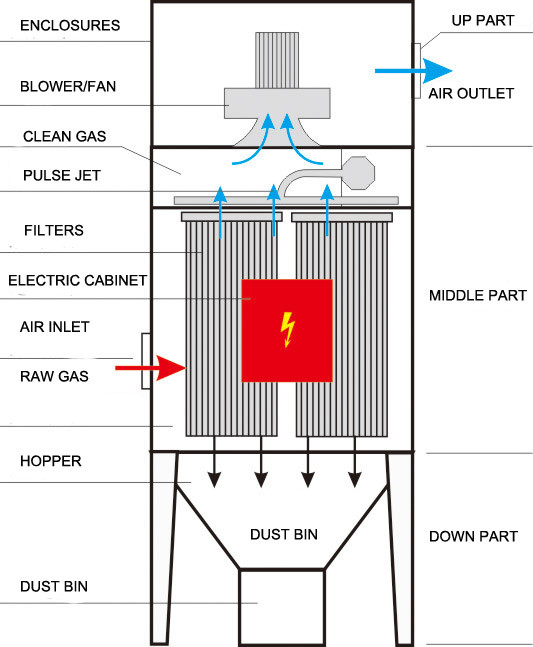

How does sinter plate dust collection machine working?

Sinter plate dust collector

Upper part: the centrifugal fan for the power source provide the airflow and full pressure, full pressure will overcome the equipment resistance and pipe resistance.

Middle part: It is including the pulse-jet system and filters in the filter room. The pulse-jet system need 0.4-0.6MP compressed air to backflow the sinter-plate filter so that the dust on the filter surface will be cleaned. The sinter-plate filter is so different from normal filter bag, it is a rigid PE sintered filter, we will illustrate on the detail on next part.

Down part: The bottom part could change depending on the dust concentration, for example dust bin or dust drawer if the dust is not too much, but need rotary feeder if the dust concentration is so high.

Control part:The control part will control the centrifugal fan and pulse-jet system, also the rotary feeder.

Working mode:

The raw gas come into the sinter-plate filter dust collector air inlet, then the dust will be purified by the sinter plate filter, then the cleaned gas will be extracted by the fan.

Cleaning mode: The filter surface if have too much dusts, the pulse-jet system will working, the compressed air will backflow, and the dust will be fallen into the dust bin.

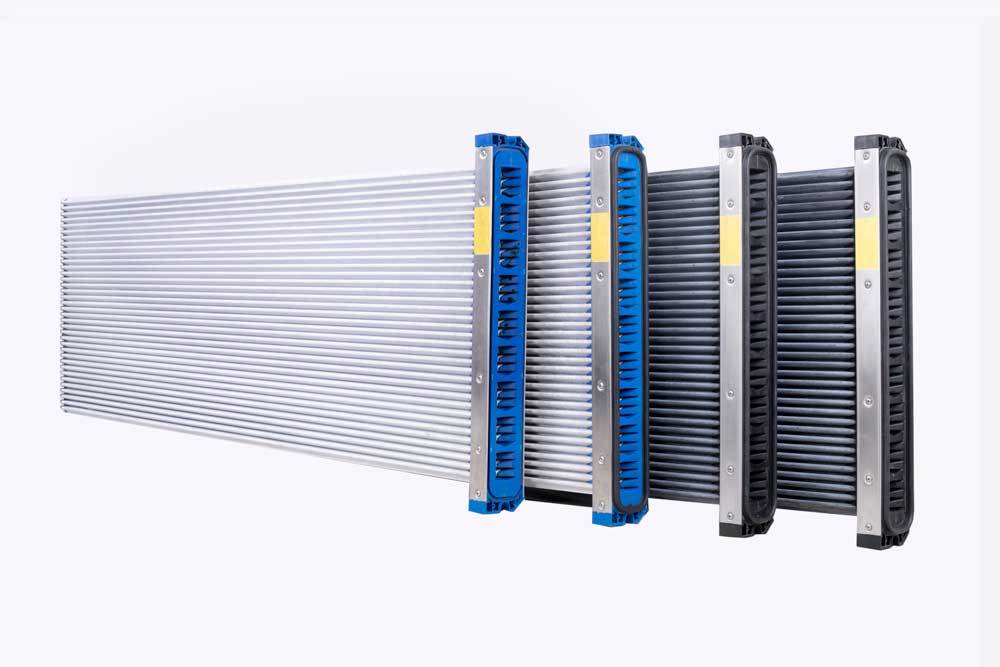

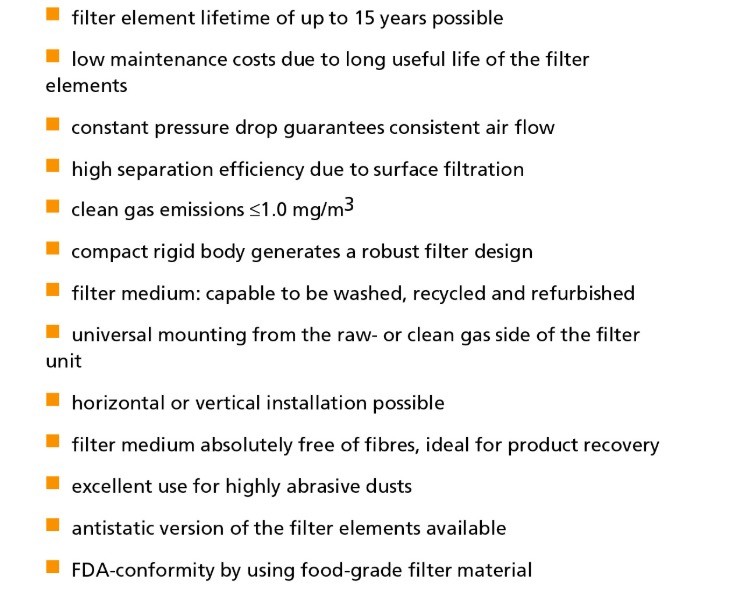

Sinter-plate filter advantages

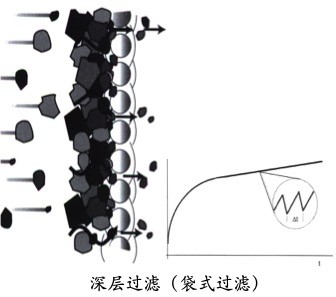

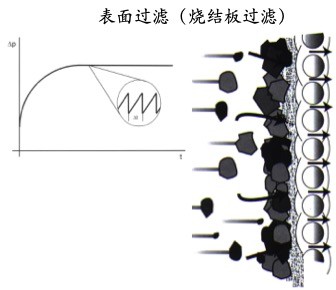

Deep filtration vs Surface filtration

Bag filters/cartridge pleated filters

Traditional filters like bag filter and cartridge filter have high efficiency when the surface dust accumulated, when the pulse-jet working the efficiency will drop, so the pressure is not stable, in some special conditions, it is not suitable.

sinter-plate filters-surface filtration

The sinter plate filter have a PTFE coating on the PE basis, so do not need dust cake to block the other dusts.

when the pulse-jet working, the efficiency will not influenced by the original conditions.

it is called surface filtration.

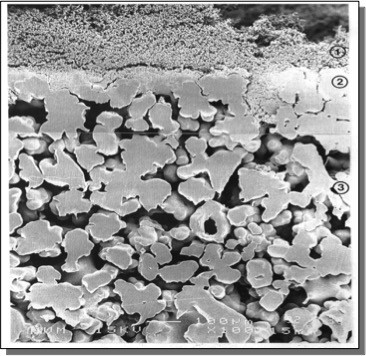

Filter anatomical structure/working principle

Big filtration area

The plicated design of the sinter-plate filter have big filtration area. our 500*1500mm size filter has 4.75m2.

so the dust collector could design small and that could save lots of space for the company. also, the rigid structure making all the folding area effective.

Sinter-plate inside view

PTFE coating: 2-3um@5um thick.

1:Sintered plate dust collector can meet the requirements of users to improve their product quality and improve user productivity.

2:Sintered plate dust collector features long life, maintenance-free and pollution-free, greatly reducing user costs

3:Extremely high filtration accuracy and filtration efficiency, especially suitable for the recovery of ultra-fine powders and high value-added powders

4:The high reliability of the equipment can work for a long time without interruption for a long time, ensuring the interests of users.

5:The overall energy consumption of the equipment is low, and the cleaning gas is returned to the work area as needed, which greatly reduces energy consumption.

6:The equipment is compact in structure, occupying a small space and saving users' land and space resources.

7:Sintered board dust collectors have been widely used and can meet the most stringent requirements for environmental protection in the future.

8:Equipment maintenance is extremely convenient and safe, saving time and effort

9:The equipment can be equipped with fireproof and explosion-proof devices, which Compliance with ISO14001 and food hygiene standards, FDA certification

Customer application

Laser cut process sinter-plate filter dust collection

So ACMAN provide a sinter-plate filter dust collection solution, on the duct before into the dust collector, we design a spark arrestor to prevent the spark come in and cooling the dust.

By using sinter-plate dust collector, customer do not need to change the filters for several years.

In addition, the emission could reach 10 mg emission.

Rare metal dust recycle dust collection

Thanks to the sinter-plate filters's great characteristics of surface filtration and wear-proof function, it could be used in the rare metal or other priceless powder recycle.

For example, the golden mine pulverizer, the silver powder recycle, zinc metal spray coating in electric elements(metal spray machine)...

Also, the 3D printer for metal, also need recycle the rare print material powder, we have application case.

This system we applied in the zinc powder recycling, and our sinter-plate dust collector help customer to catch the zinc powder dust, and save lot of cost.

Pharma coater sinter-plated filter dust extractor

This equipment in the picture shows the coater dust collection including the high pressure centrifugal fan.

The coating machine have explosive atmosphere, so we need to concern the anti-explosive measures.

In addition, this process have a cleaning mode after working, so the moisture atmosphere is harm for the dust rooms, ACMAN has its way...

Mining dust collection system

Mining process means the dust is sharp and high concentration. Other filter bags and cartridge filters is not suitable for this working condition.

Sinter-plate filter main material is rigid PE, so it is wear-proof and do not scare of the high concentration.

Iron and steel industry

Steel hot rolling process need water to cool the hot iron, the mist contain dust is a difficult task.

Sinter-plate board filter have anti-water characteristics, so it could process high moisture dusts and acid dusts.

Painting industry

Paint is strict process which need silicon proof. the silicon could make the painting bubble, so when mixing process and reaction process need dust collection filter without silicon.

Sintered PE filter do not contain the silicon could protect the products.

Videos

Related Products

Please send your message to us

- Mobile Phone

- *Title

- *Content

subscription

NAVIGATION

Categories

- Sinter-Plate Filter/Sinterlamellenfilter

- Cartridge Dust Collector

- Wet Dust Collector

- Cyclone Dust Separator

- Sinter-plate Dust Collector

- BIBO Filter Housing Unit

- Welding Fume Extractor

- Pharmaceutical Dust Collector

- HVAC Dust Collector

- Silo Bin Vent Dust Collector

- Powder Coating Dust Collector

- Laser Fume Extractor

- Centrifugal Fan

- Other Dust Collection Machine

- Baghouse/Bag Type Dust Collector

- Other HVAC Ventilation Equipments

- Pleated Dust Filters/Air Filters

- Explosion Proof Devices

- Vehicle Exhaust Hose Reels

- Keller Lufttechnik Type Dry Separator Dust Collector

KEEP IN TOUCH

Please send your message to us

- Mobile Phone

- *Title

- *Content