Home / All / Cyclone Dust Separator / ACMAN 2 Stage Dust Collector Two Stage Collection System-Cyclone with Cartridge Dust Extractor

Categories

- Sinter-Plate Filter/Sinterlamellenfilter

- Cartridge Dust Collector

- Wet Dust Collector

- Cyclone Dust Separator

- Sinter-plate Dust Collector

- BIBO Filter Housing Unit

- Welding Fume Extractor

- Pharmaceutical Dust Collector

- HVAC Dust Collector

- Silo Bin Vent Dust Collector

- Powder Coating Dust Collector

- Laser Fume Extractor

- Centrifugal Fan

- Other Dust Collection Machine

- Baghouse/Bag Type Dust Collector

- Other HVAC Ventilation Equipments

- Pleated Dust Filters/Air Filters

- Explosion Proof Devices

- Vehicle Exhaust Hose Reels

- Keller Lufttechnik Type Dry Separator Dust Collector

ACMAN 2 Stage Dust Collector Two Stage Collection System-Cyclone with Cartridge Dust Extractor

Detail Information

2 Stage Dust Collector Two Stage Collection System-Cyclone with Cartridge Dust Extractor

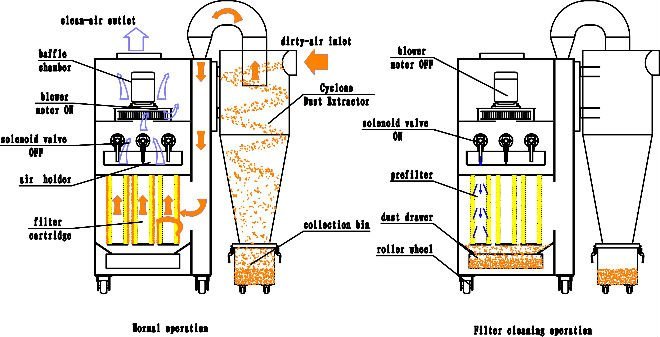

How does this two stage dust collector working

First stage: Cyclone to catch the big and heavy dust depending on the centrifugal force, the efficiency is about 70-89%, that means most of the dust will be collected by the first stage cyclone dust collector;

Second stage: Some fine dust will flow out of the cyclone, so we should have a second stage filtration machine. The second dust collector is cartridge filter pulse-jet type dust extractor, which has high efficiency and self-cleaning filters functions, also the blower/centrifugal fan plays as a traction role for this dust collection system.

On-line cleaning mode: The cartridge filter dust collector has a pulse-jet cleaning system which needs 0.4-0.6mp compressed air and the backing air flow will cleaning the filter surface on line.

Advantages

Mostly, this second stage dust collection system are widely applied in the high concentration and high density dust processes for example sandblasting...

As Pre-separator: The cyclone collector always plays a pre-separator role in the high concentration dust condition. For example: packaging, sandblasting, metal processing...

Heavy Dust Collection: Depending on cyclone dust extractor's advantage, cyclone always be used in the heavy dust collection, so the efficiency could about 89% for catching the dust.

Powder Recycle: Stainless steel cyclone are always applied in the powder recycle process, because the cyclone dust collection are easy for cleaning and washing.

Application

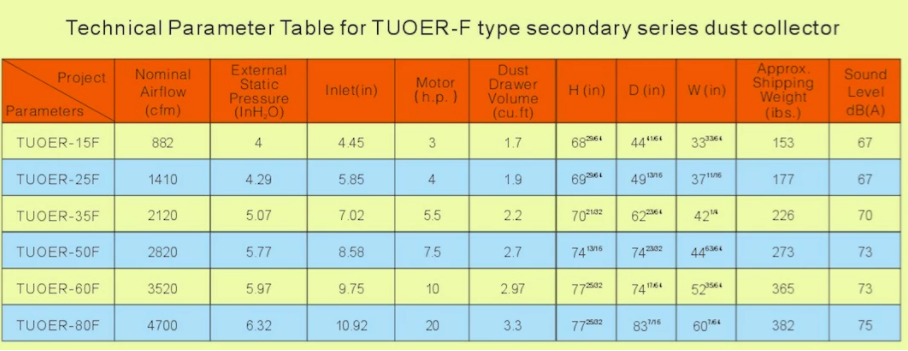

Technical Data

Customer Case Sharing

Israel customer OEM 2-stage dust collectors

This two stage dust collector is OEM for our powder recycling plant, 90% powder should be captured by the cyclone dust separator, then the cartridge filter unit catch the final dusts.

In the high concentration dust conditions is also suitable for this 2-stage dust collector, because only cartridge filters can not overcome the high concentration dust condition.

The cyclone should be made of stainless steel for recycle.

Related Products

Please send your message to us

- Mobile Phone

- *Title

- *Content

subscription

NAVIGATION

Categories

- Sinter-Plate Filter/Sinterlamellenfilter

- Cartridge Dust Collector

- Wet Dust Collector

- Cyclone Dust Separator

- Sinter-plate Dust Collector

- BIBO Filter Housing Unit

- Welding Fume Extractor

- Pharmaceutical Dust Collector

- HVAC Dust Collector

- Silo Bin Vent Dust Collector

- Powder Coating Dust Collector

- Laser Fume Extractor

- Centrifugal Fan

- Other Dust Collection Machine

- Baghouse/Bag Type Dust Collector

- Other HVAC Ventilation Equipments

- Pleated Dust Filters/Air Filters

- Explosion Proof Devices

- Vehicle Exhaust Hose Reels

- Keller Lufttechnik Type Dry Separator Dust Collector

KEEP IN TOUCH

Please send your message to us

- Mobile Phone

- *Title

- *Content