Home / All / Wet Dust Collector / Venturi Scrubber, Spray Venturi Scrubbers Manufacturers, Venturi Wet Scrubber Air Pollution Control

Categories

- Sinter-Plate Filter/Sinterlamellenfilter

- Cartridge Dust Collector

- Wet Dust Collector

- Cyclone Dust Separator

- Sinter-plate Dust Collector

- BIBO Filter Housing Unit

- Welding Fume Extractor

- Pharmaceutical Dust Collector

- HVAC Dust Collector

- Silo Bin Vent Dust Collector

- Powder Coating Dust Collector

- Laser Fume Extractor

- Centrifugal Fan

- Other Dust Collection Machine

- Baghouse/Bag Type Dust Collector

- Other HVAC Ventilation Equipments

- Pleated Dust Filters/Air Filters

- Explosion Proof Devices

- Vehicle Exhaust Hose Reels

- Keller Lufttechnik Type Dry Separator Dust Collector

Venturi Scrubber, Spray Venturi Scrubbers Manufacturers, Venturi Wet Scrubber Air Pollution Control

Detail Information

Venturi Scrubber, Spray Venturi Scrubbers Manufacturers, Venturi Wet Scrubber Air Pollution Control

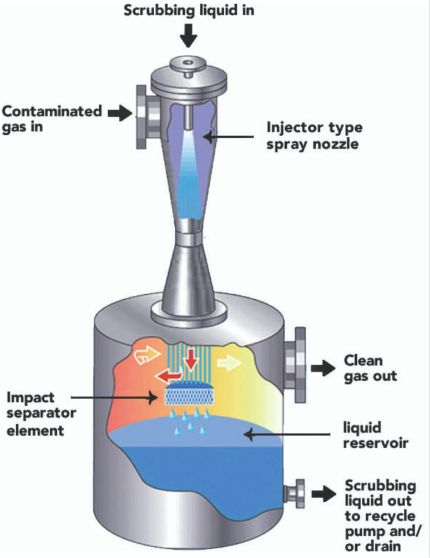

Spray venturi scrubber is a widely used and effective method for removing fine dust particles from industrial gas streams. Venturi wet scrubber, is often designed to remove fine dust from volatile, hazardous or corrosive air streams, or air streams containing solid particles that are difficult to handle. A Venturi Scrubber accelerates the waste air in order to atomize it components. Going through the "throat" part of the Venturi scrubber, the air velocity rise because of the narrowing of the throat, then it expands again in the open space. Clean water is introduced to the air stream in this throat part and is atomized into small droplets from the acceleration in the scrubber. As the water particles went through the venturi wet scrubber, small waste dust from the gas stick to the water and is collect.

Inner Working Theory

Venturi Scrubber Operation

Flow rate: 720 -100 000 Nm3/h

Temperature: 4 -1 000 °C

In-coming concentrations: 1 -115 g/Nm3

Tangential inlet ports ensures the walls are fully wetted to eliminate wet/dry line build-up. Scrubbing liquid is introduced into the Venturi throat through open pipes to ensure uniform liquid distribution for maximum particulate collection. Dust-laden gas and scrubbing liquid collide in the throat. This disperses the liquid into drops on which the particles impact and become trapped.

Application

Venturi scrubbers are used in a wide range of applications including medical, hazardous, and industrial waste incineration, pot ash mining, mineral processing, sewage sludge drying, coal drying, CPVC plastic manufacturing, copper roasting, tire manufacturing, glass and insulation manufacturing, pyrolysis and gasification syngas cleaning, and waste to energy production

The chemical industry, to separate dust and aerosols;

The metal industry for various types of waste gases;

Waste incineration installations;

Gasification processes;

Potato-processing industry for the removal of starch;

Glass industry;

Melting processes in metallurgy;

Foundries;

Sintering processes;

Drying processes;

Fertiliser production;

Pharmaceutical industry;

Plastics industry

Advantages

1: Venturi scrubbers collect coarse or fine particulate, including particulate under 1 micron and particulate that is sticky or high in moisture;

2: Venturi scrubbers accommodate high temperature gas streams, including those from casting, sintering, glass manufacturing, incineration and pyrolysis;

3:Venturi scrubbers accommodate high temperature gas streams, including those from casting, sintering, glass manufacturing, incineration and pyrolysis;

4: Venturi systems are suitable for high dust loadings;

5: Venturi systems are continuously wetted, and are not vulnerable to clogging, plugging, scaling, or wet/dry line build-up in the machine;

6: Collection efficiency for venturi scrubbers is 89-98.5%, (depending on the number of stages);

7: Slurries that contain high concentrations of solid material, or valuable material, can be recycled.

Disadvantages

1: Large pressure drops;

2: Signs of erosion when scrubbing abrasive mediums;

3: The water recycle pump and nozzle has risk of clog;

Technical Data

Model | Air Volume (m3/h) | Body Diameter (mm) | Pump Power (kw) | Water Tank Volume(L) | Air Inlet/Outlet (mm) |

FCT-10 | 1000-1500 | Φ600 | 0.75 | 250L | Φ150/200 |

FCT-20 | 1688-2476 | Φ700 | 0.75 | 500L | Φ175/233 |

FCT-30 | 2664-3405 | Φ820 | 0.75 | 600L | Φ240/300 |

|

FCT-40 |

3786-4527 |

Φ950 |

0.75 |

700L | Φ280/255 |

FCT-60 | 4973-6457 | Φ1100 | 0.75 | 1000L | Φ320/390 |

|

FCT-80 |

7081-8489 |

Φ1220 |

1.5 |

1200L | Φ390/390 |

|

FCT-100 |

8490-10455 |

Φ1360 |

1.5 |

1300L | Φ400/450 |

|

FCT-120 |

10400-13455 |

Φ1500 |

1.5 |

1800L | Φ440/500 |

Our Applications

Related Products

Please send your message to us

- Phone

- *Title

- *Content

subscription

NAVIGATION

Categories

- Sinter-Plate Filter/Sinterlamellenfilter

- Cartridge Dust Collector

- Wet Dust Collector

- Cyclone Dust Separator

- Sinter-plate Dust Collector

- BIBO Filter Housing Unit

- Welding Fume Extractor

- Pharmaceutical Dust Collector

- HVAC Dust Collector

- Silo Bin Vent Dust Collector

- Powder Coating Dust Collector

- Laser Fume Extractor

- Centrifugal Fan

- Other Dust Collection Machine

- Baghouse/Bag Type Dust Collector

- Other HVAC Ventilation Equipments

- Pleated Dust Filters/Air Filters

- Explosion Proof Devices

- Vehicle Exhaust Hose Reels

- Keller Lufttechnik Type Dry Separator Dust Collector

KEEP IN TOUCH

Please send your message to us

- Phone

- *Title

- *Content