Home / All / Keller Lufttechnik Type Dry Separator Dust Collector / KELLER VARIO ECO Type Dust Collector-For Highly Effective, Energy-efficient Dry Separation of Fine Dust

Categories

- Sinter-Plate Filter/Sinterlamellenfilter

- Cartridge Dust Collector

- Wet Dust Collector

- Cyclone Dust Separator

- Sinter-plate Dust Collector

- BIBO Filter Housing Unit

- Welding Fume Extractor

- Pharmaceutical Dust Collector

- HVAC Dust Collector

- Silo Bin Vent Dust Collector

- Powder Coating Dust Collector

- Laser Fume Extractor

- Centrifugal Fan

- Other Dust Collection Machine

- Baghouse/Bag Type Dust Collector

- Other HVAC Ventilation Equipments

- Pleated Dust Filters/Air Filters

- Explosion Proof Devices

- Vehicle Exhaust Hose Reels

- Keller Lufttechnik Type Dry Separator Dust Collector

KELLER VARIO ECO Type Dust Collector-For Highly Effective, Energy-efficient Dry Separation of Fine Dust

Detail Information

KELLER VARIO ECO Type Dust Collector-For Highly Effective, Energy-efficient Dry Separation of Fine Dust

The VARIO eco series is particularly suitable for the separation of fine dust. Most classes of dust can be successfully separated. Significant separation efficiency is achieved with very low energy usage.

Excellent filter performance with low energy requirements

VARIO eco was improved to minimize energy consumption. Savings are achieved with more efficient fans as well as reduced compressed air consumption during filter element cleaning. High degree of separation efficiency allows air recirculation back into the workplace.

VARIO eco was improved to minimize energy consumption. Savings are achieved with more efficient fans as well as reduced compressed air consumption during filter element cleaning. High degree of separation efficiency allows air recirculation back into the workplace.

TASK

The VARIO eco series is particularly suitable for separation of fine dust. Nearly all types of dust can be successfully separated, such as those created in metal processing, polymer processing, and in chemical, pharmaceutical and ceramic industries, as well as non-metallic minerals.

The VARIO eco units are of modular construction in order to meet different requirements, such as dust characteristics or the volume of exhausted air. Sturdy and low-noise units allow for reliable 24-hour operation with constant air flow.

ECO = as much energy as necessary

The VARIO was further improved to minimize energy consumption. Savings are achieved by using more efficient fans as well as reducing compressed air consumption during filter element cleaning. Lower filter resistance by state-of-the-art KLR filters results in additional savings, since use of the fan can be significantly decreased.

Advantages

• Reduced sound with integrated sound insulation for sizes VARIO 1 - 3 eco

• Flexible design

• Flexible setup

• Integrated deflection design for protection against wear and improved air distribution

• Easily accessible inspection doors

Function

The dust-laden air flows through the dirty air inlet into the filter unit. A baffle plate slows down and deflects the dust particles to protect the filter elements from direct impact. An air down-flow is created between the filter elements, allowing the dust particles to drop. A fan in the clean air chamber draws the polluted air through the filter elements, depositing the dust particles onto the filter surface. Because the filter elements are cleaned continuously by compressed air pulses during operation, the air flow remains constant. The cleaned air exits through the top of the unit and in most cases can be re-circulated into the work area or vented outdoors. The separated dust falls into the dust collector containers.

Filter elements

Cartridges or plate filters are used, depending on the application, for enhanced separation efficiency and service life. All filter elements used are of high quality and easy to clean.

Cleaning the filter elements

The pulse cleaning cycle can be adjusted for each application by means of an integrated control unit. The air flow of the fan remains nearly constant. The cleaning operation is activated either by a differential pressure regulator while in operation, or by a programmable downtime cleaning cycle.

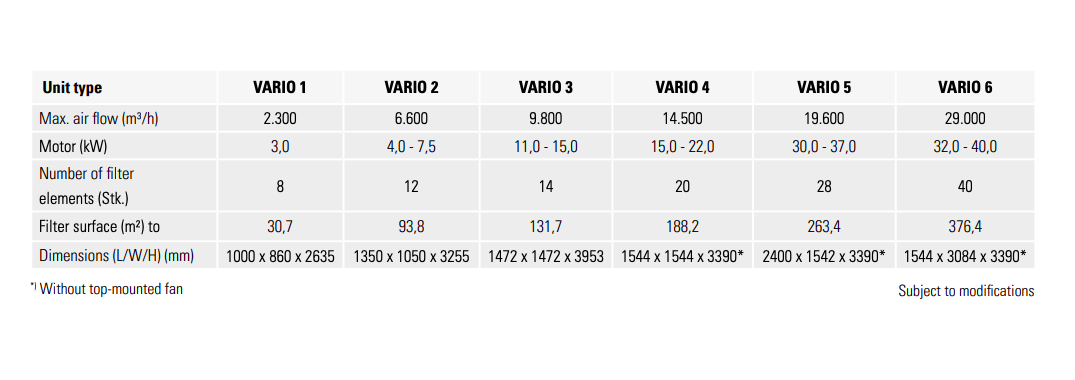

Technical Data for keller Vario Series dry separator

Our Factory OEM photos for Keller Lufttechnik China

Please send your message to us

- Phone

- *Title

- *Content

subscription

NAVIGATION

Categories

- Sinter-Plate Filter/Sinterlamellenfilter

- Cartridge Dust Collector

- Wet Dust Collector

- Cyclone Dust Separator

- Sinter-plate Dust Collector

- BIBO Filter Housing Unit

- Welding Fume Extractor

- Pharmaceutical Dust Collector

- HVAC Dust Collector

- Silo Bin Vent Dust Collector

- Powder Coating Dust Collector

- Laser Fume Extractor

- Centrifugal Fan

- Other Dust Collection Machine

- Baghouse/Bag Type Dust Collector

- Other HVAC Ventilation Equipments

- Pleated Dust Filters/Air Filters

- Explosion Proof Devices

- Vehicle Exhaust Hose Reels

- Keller Lufttechnik Type Dry Separator Dust Collector

KEEP IN TOUCH

Please send your message to us

- Phone

- *Title

- *Content