Home / All / BIBO Filter Housing Unit /

Single Stage Safe Change H14 BIBO System HEPA Filter Housing Unit with PAO Charging Port-Bag In Bag Out

Categories

- Sinter-Plate Filter/Sinterlamellenfilter

- Cartridge Dust Collector

- Wet Dust Collector

- Cyclone Dust Separator

- Sinter-plate Dust Collector

- BIBO Filter Housing Unit

- Welding Fume Extractor

- Pharmaceutical Dust Collector

- HVAC Dust Collector

- Silo Bin Vent Dust Collector

- Powder Coating Dust Collector

- Laser Fume Extractor

- Centrifugal Fan

- Other Dust Collection Machine

- Baghouse/Bag Type Dust Collector

- Other HVAC Ventilation Equipments

- Pleated Dust Filters/Air Filters

- Explosion Proof Devices

- Vehicle Exhaust Hose Reels

- Keller Lufttechnik Type Dry Separator Dust Collector

Single Stage Safe Change H14 BIBO System HEPA Filter Housing Unit with PAO Charging Port-Bag In Bag Out

| Categories | BIBO Filter Housing Unit |

|---|---|

| Brand | ACMAN |

| Model | BIBO-H-CFM |

| FOB port | SHANGHAI/NINGBO |

| Terms of Payment | T/T |

| Update Time | Jul 17,2025 |

Detail Information

Single Stage Safe Change H14 BIBO System HEPA Filter Housing Unit with PAO Charging Port-Bag In Bag Out

Bag-in and bag-out filters appeared in the 1950s and 1960s, and are currently widely used in a variety of high-risk or high isolation requirements, such as: chemical and biological (CB) protection, chemical, biological and radiological ( CBR) protection, nuclear chemical, biological and chemical (NBC) protection, hospital isolation room, pharmaceutical equipment, microelectronics environment, food processing area, biological research, genetic and biotechnology laboratory, industrial processing discharge system, chemical processing equipment, animal Disease research laboratories, radioisotope processing equipment, nuclear power plants, strategic nuclear facilities, DOE equipment, military bases, etc.

How does single stage BIBO HEPA filter unit working?

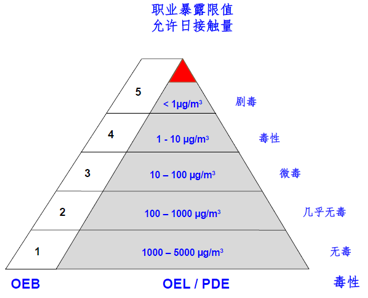

The equipment design refers to the leakage limit of the international OEB standard, and the overall design is in accordance with the control of the 1ug/m³ dust leakage rate and meets the requirements of the OEB5 standard

Bag-in-bag-out filter, namely Bag In Bag Out Filter, usually referred to as BIBO, is also known as a duct-type exhaust high-efficiency filter device. Since the filter has retained highly active or highly toxic harmful aerosols during the working process, it is necessary to ensure that the filter does not have any contact with the external environment during the replacement process.

The entire process of filter replacement is carried out in a sealed bag, so it is called bag entry Bag out the filter. Its use can effectively prevent the spread of harmful aerosols and avoid biological hazards to personnel and the environment. It is a filter device used in specific biological risk environments to remove harmful biological aerosols in the exhaust air. Generally, it has in-situ disinfection. And leak detection function, in the process of use, it needs to be equipped with biological sealing valve and other components.

Commonly used functional units include: Pre-filter, HEPA, HEGA, Precision ScanTest Sections, etc. The simplest filter unit only contains a high-efficiency particle filter. If there is no other filtering device before the air enters the bag into the bag and exits the filter, you need to configure a pre-filter to protect the high-efficiency particle filter. If the filtered gas has adsorption requirements, it is equipped with high-efficiency Gas adsorption filter; detection unit refers to automatic (or manual) fine scanning detection device.

Advantage

1: High Security: The AC.Safe. BIBO filter equipment has air tight welding housing to prevent the leakage of contaminated material. In addition, A differential gauge with screen and output port is standardly equipped on the bag in-bag out filter box to test the leakage.

2: Negative pressure design: The AC.Safe. filtering system unit could sustain -5000Pa pressure.

3: Door easily remove:The door are specially designed for the tightness and convenience. Only four bolt fastening could easily remove the access doors, but the inner sealing also protect the leakage.

4: Two HEPA filters equipped: the first HEPA is the mainly filtering step, and second HEPA is the protective HEPA.

How to change the HEPA Filters?

Step1: Open the doors

Step 2: Tight the safety bag

Step 3: Pull out of the HEPA

Step 4: seal Bag/Remove

Step 5: Tight another bag with Hepa, remove the first bag.

Step6: Insert the Hepa and close the door

1 Stage HEPA Filter Housing Station Technical Data

|

Model |

Airflow(m3/h) |

HEPA Size(mm) |

HEPA Quantity(pcs) |

BIBO-H-500CFM | 850 | 484*484*220 | 1 |

BIBO-H-1000CFM | 1700 | 592*592*292 | 1 |

BIBO-H-2000CFM | 3400 | 592*950*292 | 1 |

|

BIBO-H-4000CFM |

6800 |

592*950*292 |

2 |

|

BIBO-H-6000CFM |

10200 |

592*950*292 |

3 |

Video

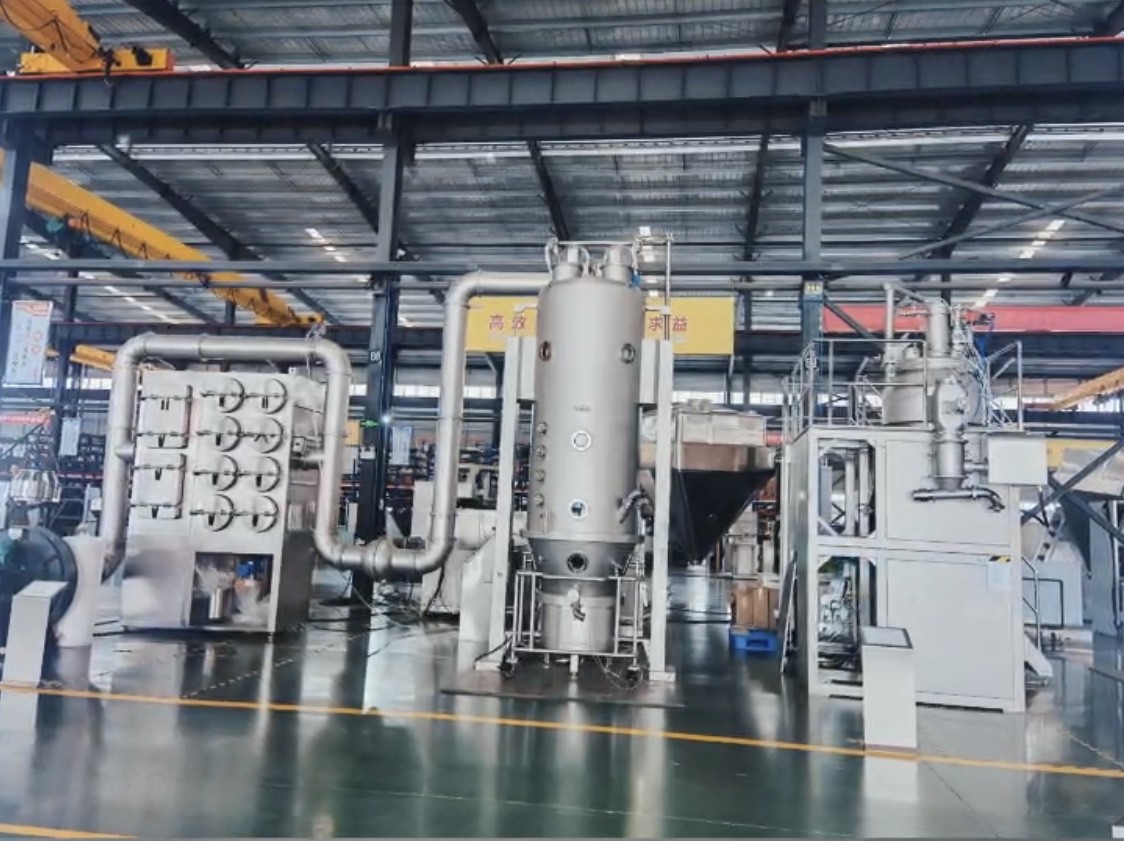

Fluidized bed BIBO filter unit application

Related Products

Please send your message to us

- Tel

- *Title

- *Content

subscription

NAVIGATION

Categories

- Sinter-Plate Filter/Sinterlamellenfilter

- Cartridge Dust Collector

- Wet Dust Collector

- Cyclone Dust Separator

- Sinter-plate Dust Collector

- BIBO Filter Housing Unit

- Welding Fume Extractor

- Pharmaceutical Dust Collector

- HVAC Dust Collector

- Silo Bin Vent Dust Collector

- Powder Coating Dust Collector

- Laser Fume Extractor

- Centrifugal Fan

- Other Dust Collection Machine

- Baghouse/Bag Type Dust Collector

- Other HVAC Ventilation Equipments

- Pleated Dust Filters/Air Filters

- Explosion Proof Devices

- Vehicle Exhaust Hose Reels

- Keller Lufttechnik Type Dry Separator Dust Collector

KEEP IN TOUCH

Please send your message to us

- Tel

- *Title

- *Content